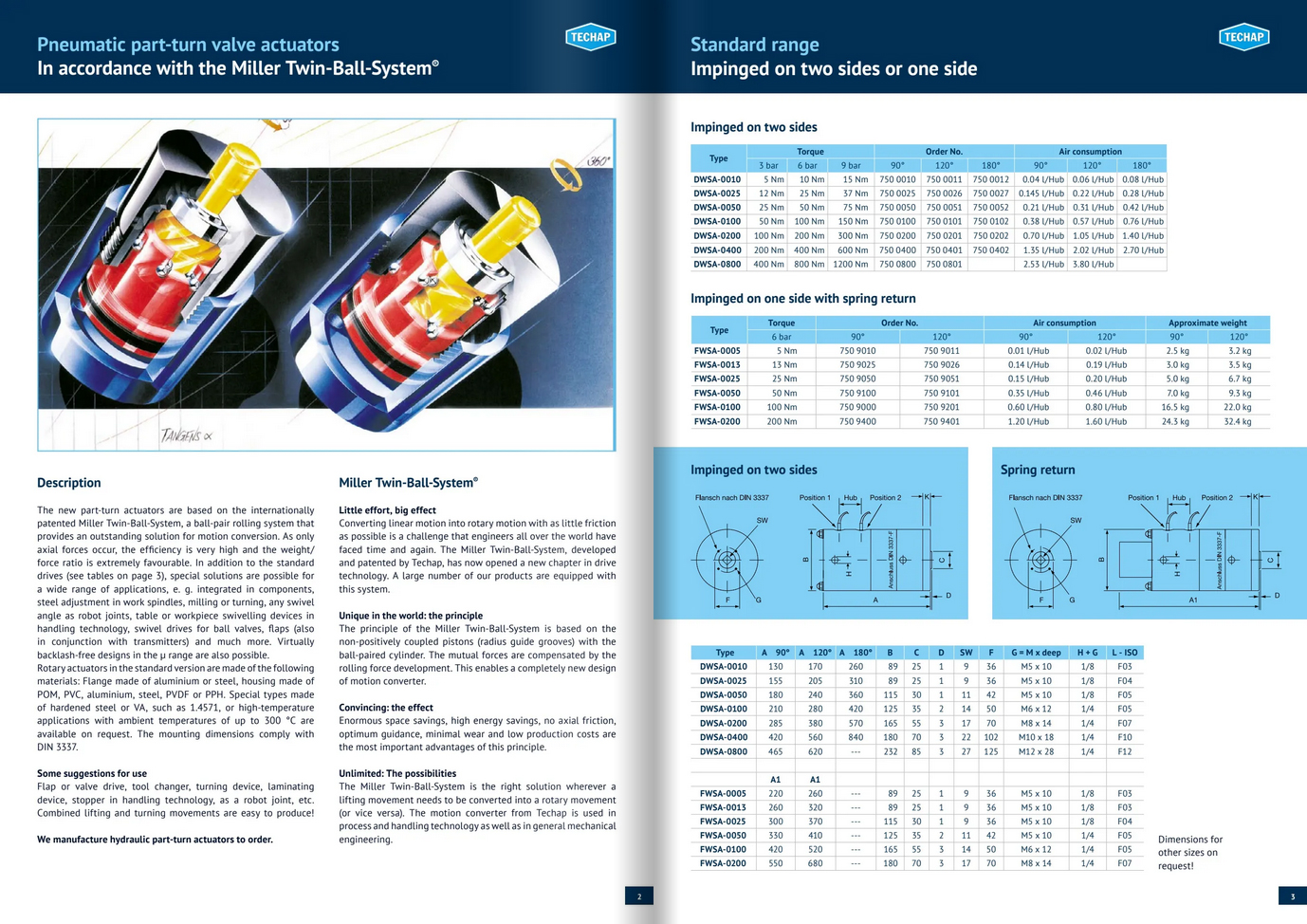

Pneumatic part-turn valve actuators in accordance with the Miller Twin-Ball-System®

The new part-turn actuators are based on the internationally patented Miller Twin-Ball-System, a ball-pair rolling system that provides an outstanding solution for motion conversion. As only axial forces occur, the efficiency is very high and the weight/force ratio is extremely favourable. In addition to the standard drives, special solutions are possible for a wide range of applications, e. g. integrated in components, steel adjustment in work spindles, milling or turning, any swivel angle as robot joints, table or workpiece swivelling devices in handling technology, swivel drives for ball valves, flaps (also in conjunction with transmitters) and much more. Virtually backlash-free designs in the μ range are also possible.

Rotary actuators in the standard version are made of the following materials: Flange made of aluminium or steel, housing made of POM, PVC, aluminium, steel, PVDF or PPH. Special types made of hardened steel or VA, such as 1.4571, or high-temperature applications with ambient temperatures of up to 300 °C are available on request. The mounting dimensions comply with DIN 3337.

Some suggestions for use

Flap or valve drive, tool changer, turning device, laminating device, stopper in handling technology, as a robot joint, etc. Combined lifting and turning movements are easy to produce!

More info

![Chemical vapour locks® [Translate to English:]](/fileadmin/Redakteure/01_Produkte/01_Chemikaliendampfschloesser/chemikaliendampf.jpg)

![Injectors [Translate to English:]](/fileadmin/Redakteure/01_Produkte/08_Injektoren/injektoren.jpg)

![Ball reflux regulating valves [Translate to English:]](/fileadmin/Redakteure/01_Produkte/09_Kugel-Rueckschlag-Regulierventile/kugel-rueckschlag.jpg)

![Conductance measuring electrodes [Translate to English:]](/fileadmin/Redakteure/01_Produkte/11_Leitwert-Messelektroden/leitwert-messelektroden.jpg)

![Pneumatic part-turn valve actuators [Translate to English:]](/fileadmin/Redakteure/01_Produkte/12_Pneumatik-Schwenkantriebe/pneumatik-schwenkantriebe.jpg)

![Level Switches [Translate to English:]](/fileadmin/Redakteure/01_Produkte/13_Niveau-Schalter/niveauschalter.jpg)

![Ceramic flat-side valves [Translate to English:]](/fileadmin/Redakteure/01_Produkte/14_Keramik-Flachschieber/keramikflachschieber.jpg)