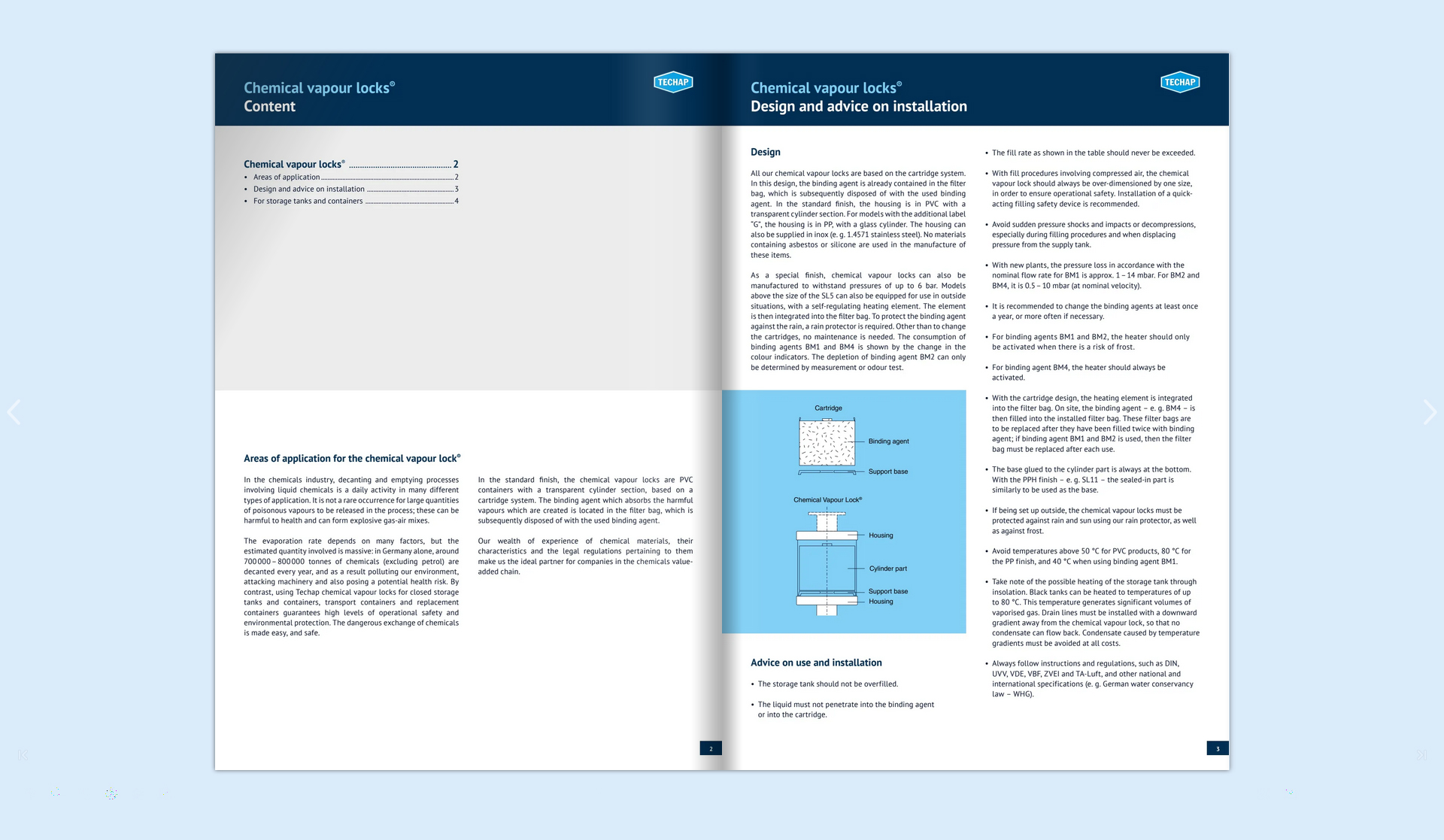

Chemical vapour locks

In the chemical industry, transfer and emptying processes of liquid chemicals are used daily in many areas of application. This often releases large quantities of toxic vapours that are harmful to health and can form corrosive or explosive gas-air mixtures.

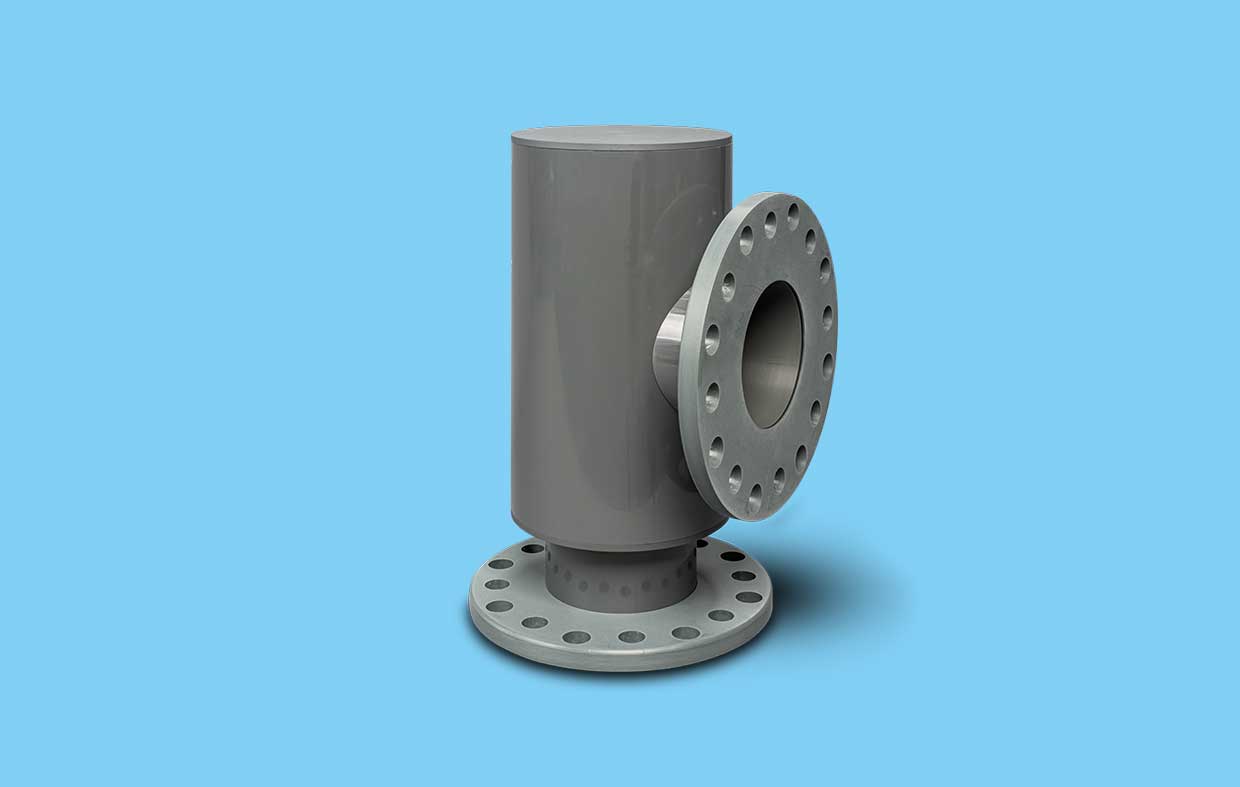

The evaporation rate of liquid chemicals depends on many factors, but the estimated quantity is enormous: 700,000 - 800,000 tonnes of chemicals (excluding petrol) are transferred every year in Germany alone, polluting our environment, damaging machinery and also endangering people's health. Techap's chemical vapour locks for closed storage tanks and containers, transport containers and swap bodies, on the other hand, ensure a high level of operational safety and environmental protection. This makes the hazardous filling and emptying of chemical tanks easy and safe. The Techap advantage here is the extremely low pressure loss, which enables installation for any type of tank. The intelligent cartridge system makes it easy to change the filter material. Flow rates from 200 to 150,000 litres are possible. With accessories such as heaters and rain hats, the chemical vapour locks are also suitable for both indoor installation and extreme outdoor weather conditions.

Techap has the right solution for all common chemicals.

Thanks to our many years of knowledge of chemical substances, their properties and legal categorisation, we are the ideal partner for companies in the chemical recycling chain.

Enquiry chemical vapour locks

FAQ - Chemical vapour locks

Techap offers chemical vapour locks for volume flows of up to 150 m3/h. Higher volume flows are easily possible by arranging vapour locks in parallel. When dimensioning, the maximum permitted pressure loss should always be taken into account. This is usually defined by the load limits for vacuum or overpressure of the tank. If additional equipment, such as a Techap quick-fill safety device, is used or CO2 is to be absorbed, the vapour lock must be selected one size larger than actually required in order to ensure operational safety on the one hand and to guarantee sufficient dwell time of the air flow in the binding agent on the other.n, um einerseits die Betriebssicherheit zu gewährleisten und andererseits eine ausreichende Verweilzeit des Luftstroms im Bindemittel zu gewährleisten.

Some of our binders are equipped with colour indicators that show saturation in colour. In the case of activated carbon, for example, it makes sense to measure pollutants to monitor the concentration after the vapour lock in order to make maximum economic use of the binder filling. The activated carbon is used for as long as the concentration of the exhaust gas is below the required limit value.

Our chemical vapour locks are used in industry and the food and pharmaceutical sectors for filtering or absorbing/adsorbing harmful chemical exhaust gases of all kinds. Chemical vapours are released, for example, when filling chemical tanks or during the storage of chemicals. Furthermore, in combination with a regenerable drying agent, they can protect hygroscopic media from moisture. Chemical vapour locks can also be used to effectively prevent CO2 from entering tanks containing deionised, demineralised or distilled water, for example, by removing it from the incoming air when the tank is emptied.

In principle, the exhaust gases of all chemicals in circulation can be filtered by our binding agents. Individual examples include hydrochloric acid, nitric acid, sulphuric acid and ammonia. Thanks to our extensive expertise and many years of experience, we are able to find the right binding agent even for complicated chemicals.

The selection of suitable binders requires a great deal of experience. For this reason, the binder is selected by our team of experts in Leonberg after the customer-specific data has been provided. Factors such as the temperature of the medium and the environment or the concentration and pH value of the chemical are decisive here.

![Chemical vapour locks® [Translate to English:]](/fileadmin/Redakteure/01_Produkte/01_Chemikaliendampfschloesser/chemikaliendampf.jpg)

![Injectors [Translate to English:]](/fileadmin/Redakteure/01_Produkte/08_Injektoren/injektoren.jpg)

![Ball reflux regulating valves [Translate to English:]](/fileadmin/Redakteure/01_Produkte/09_Kugel-Rueckschlag-Regulierventile/kugel-rueckschlag.jpg)

![Conductance measuring electrodes [Translate to English:]](/fileadmin/Redakteure/01_Produkte/11_Leitwert-Messelektroden/leitwert-messelektroden.jpg)

![Pneumatic part-turn valve actuators [Translate to English:]](/fileadmin/Redakteure/01_Produkte/12_Pneumatik-Schwenkantriebe/pneumatik-schwenkantriebe.jpg)

![Level Switches [Translate to English:]](/fileadmin/Redakteure/01_Produkte/13_Niveau-Schalter/niveauschalter.jpg)

![Ceramic flat-side valves [Translate to English:]](/fileadmin/Redakteure/01_Produkte/14_Keramik-Flachschieber/keramikflachschieber.jpg)