|

|

||

| |

|

||

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

|

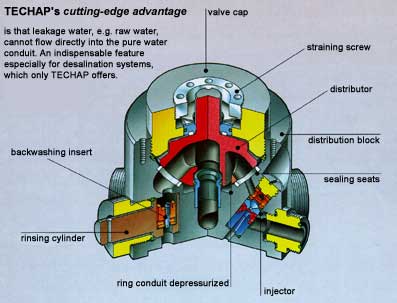

| TECHAPís

High-Performance Process Valves DN 20/32/40/65/80 |

|

|

|

| A SHORT CHARACTERISATION OF OUR PRODUCT LINES | |

|

UVK line

of products for conventional operation |

|

| UVG

line of products for counterflow fluidised bed operation The water flows from bottom to top through the resin ( = the operating phase) and it is suspended. Regeneration: from bottom to top. Resin turbulences and rearrangement have to be avoided. Inert resin is necessary. The order of functions: operation, suctioning, displacing and washing. |

|

| UVR

line of products for backflow regeneration Fixed bed operation. The water flows from top to bottom (fixed bed) through the resin ( = the operating phase). Regeneration: from bottom to top. Resin turbulences and rearrangement have to be avoided. Inert resin is necessary. The order of functions: operation, suctioning, displacing and washing. |

|

| UVM

line of products for mixed bed operation The water flows from top to bottom through the resin ( = the operating phase) forming a fixed bed. Regeneration: with alkaline solution from the top, with acid from the bottom, both to the centre distribution system. Aeration and dearation is necessary for the resin mixture. The order of functions: operation, backrinsing/separating, suctioning and washing. |

|

| THE DESIGN OF TECHAP VALVES | |

|

|

TOP